Toronto brick maker brings expertise to Marmora

by Gerald Belanger

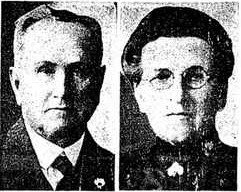

Marmora's first commercial brickyard was made prosperous by brick maker John William Nayler. Born in Brixton, Kent County, England, John and his family emigrated and settled in the Belleville area when he was very young. On October 26, 1876, John married Annie Lavinia Butwell, daughter of Mr. and Mrs. Henry Butwell. The Butwell's had also emigrated from England and made their new home in Toronto.

Henrry Butwell

Great story about Ada Nayler Butwell Forsyth (perhaps John Nayler's sister?) by Pat Staton January 24, 2000

Ada Nayler was born in the village of Penge in Surrey, England, January 12, 1868. She was the youngest child of James Nayler and Eliza Harris. Her father was a brick maker. When she was three years old, her family emigrated to Canada. They were among thousands of immigrants from England, Ireland, Scotland and Europe who endured terrible hardships on cross Atlantic voyages. The Naylers settled in Madoc, near Belleville, Ontario.

The family’s first home was a log cabin similar to the cabin the well known pioneer, Susannah Moodie, described in Roughing It In The Bush.

Ada attended school only until Grade 4 when her father died. All the children had to leave school to help support the family, so Ada was apprenticed as a maidservant to a local family. Eliza Nayler took comfort that her youngest child was nearby and would be well fed. Ada’s work included cleaning fireplaces, carrying firewood, cleaning boots, sweeping and dusting, feeding the chickens and helping with laundry.

This was Ada’s life until 1888, when she and her sister Eliza were married in a double wedding ceremony to Richard and Mark Butwell, the sons of another brickmaker. The couples moved to Toronto, where Ada’s father-in-law, Henry Butwell, had opened a brickyard near Clinton and Bloor.

Ada was considered a great beauty as a girl and received a number of marriage proposals. Just before her wedding, one of the disappointed young men, John Forsyth, called to her across the crowded main street that she was the most beautiful woman he had ever seen. One day she would be his wife “no matter how long I have to wait!”

For the next 30 years, Ada cooked, cleaned, and sewed for her family. She had four children who survived: Laura 1892, Arthur 1894, Ross 1896 and Doris 1908. In addition to child care, housework, the care of chickens, two dairy cows and a horse, she prepared a hot noon meal six days a week for the five men who worked in the brickyard. Ada also made butter which she sold to the T. Eaton Company. Every Saturday afternoon, she hitched up the horse and buggy for the drive to the Eaton store in downtown Toronto. There she sold her butter to Mr. Timothy Eaton. When Ada was an old woman, she liked to tell her grandchildren that Mr. Eaton always said she made the best butter and he always gave her the best price. The money she earned from butter and eggs provided the only cash income the family could depend on. In return for working 11 hours a day in his father's brickyard, Ada's father was given a rent-free house, a horse, chickens and occasional cash payments. Ada’s tremendous workload was taken for granted in her day. When the 1891 census was taken, Ada was asked if she worked. She said “No.” Her occupation is listed in the census as “housewife.”

Henry, the family patriarch, died in 1921 leaving his brickyard, construction business and real-estate holdings equally divided among his ten children. (See Butwell Brothers below) His death was followed by years of family struggles for control, which led to lawsuits and decline into near-bankruptcy. Ada’s husband, who eventually assumed responsibility for the brickyard, had no education (he could not read), no head for business, and preferred spending his time at John Duck’s Tavern in Humber Bay with his cronies. His accidental death on a fishing trip in 1933, around the time the business failed, left Ada at 65 with almost nothing except the large brick family home on Lakeshore Boulevard. She survived by renting out the second floor bedrooms and keeping a garden. Her children helped when they could, but they had their own young families to support.

In the 1930s and 1940s, the large house on the lake was filled on weekends and summer holidays with her seven grandchildren. We swam and played on the beach in the summer. Rainy days and winter Sundays found us up in the attic ransacking trunks and boxes for costumes for the dramatic productions we created. An old, hand-cranked victrola provided background music, not always strictly in keeping with the blood curdling themes of our plays.

The sale of the house in the mid-1940s allowed Ada to retire in comfort to a small bungalow not far from her oldest daughter and a short walk to church. One day, Ada answered a knock on her front door. John Forsyth stood on the porch holding a large bouquet of red roses. He had married and had a family, he told her, and his wife had died exactly one year earlier. He had come to keep his promise. Ada and John eloped to Niagara Falls and telephoned the news of their marriage. Her sons were horrified and called it a scandal; her daughters were pleased for her. Ada and John had only a few years together, but those years were filled with love and companionship.

Henry Butwell was engaged in the manufacture of clay bricks on a very large scale in the Toronto area for over sixty-five years. He was the foreman brick-maker at the Central Prison located on Strachan Avenue. It is believed that shortly after John and Annie were married, they settled near Toronto. It was perhaps while there that John learned the brick makers trade from Henry.

By 1884, John and Annie were living in Stirling. By the early 1890's they had moved their family to Marmora where John worked at George Loucks brickyard. Loucks was at that time over seventy-six years of age and looking to sell his brick business, located just south of Highway No. 7 by the east end of the Marmora Protestant Cemetery. At the time, the Loucks property extended from the corner of Victoria Avenue east on both sides of Madoc Street to just past North Maloney Street.

After the death of George Loucks on October 19, 1898, Nayler purchased his property and two storey brick residence from the Loucks estate. The Nayler residence was later purchased by the Village on May. 20, 1920 and converted into the Marmora Continuation School.

John and Annie Nayler raised eleven children ~

Mrs Myrtle Nayler Rombough

John Henry

Albert (Link) Wm, Campbellford

Walter, Niagara

Robert, Marmora

Clarence, Marmora

Theodore, Marmora

Gertrude Fry, Campbellford

Winnifred Ethel, Lindsay

Harold Percy, Marmora

Norman Cecil, Schumacher, Ontario

Myrtle Lavina Rombough

Norman’s granddaughter, Mary-Ann Nayler Baillie writes:

My father, Gerald R. Nayler, was born in Schumacher to Norman Cecil Nayler and Charlotte Dora Turcotte. Norman was a young son of John Nayler and Annie Buttwell. Norman took his young family to Red Lake, ON to prospect for gold. He passed away there in 1964. Gerald married Grace Middleton from Winnipeg, MB and settled in Toronto for several years and then to Pinawa, MB where Gerald worked for AECL (Atomic Energy Research). He passed away at the age of 84 at his cottage in Perrault Falls, ON in September of 2009. His children Mary-Ann, Sherry, Laurie, Warren & Lisa live in various towns and cities in Ontario and Manitoba.

At one time or another, all of John's sons worked at the brickyard, which usually employed 10 to 12 men, except during the winter months when bricks could not be manufactured. The clay for the bricks was taken and baked in kilns in the area that is now referred to as Nayler's Common Wetland and Trails. The kilns were built by hand and fired by wood continually for at least a week using 40 to 60 cords of soft wood at a time. About 70 to 80 thousand bricks would be baked in the kilns at least three to four times a year.

William Arthur Shannon, who lived with his parents, Daniel Shannon and Sarah Donahue, on Madoc Street, recalled that, as a boy, he could see the horses at work in the brickyard going round and round mixing the clay for the bricks.

Excerpt from 1908 Provincial Mining Report regarding John W Nayler

Locality: Marmora Capacity of works: 200,000 brick per season. Number of men employed: 6 Wages paid January 50 cents to $2 per day

The red clay in this yard, which is about 2 feet deep with gravel and marl below, is air slaked and wheeled direct to a The Doig four brick machine. Bricks are hacked and burned to dry in open scove kilns with wood.( or as it is commonly called, the Dutch clamp kiln.)

The market place is local. Horse power is used. The bricks are very brittle brick The clay is generally loamy and contains limestone pebbles which causes many of the brick to crack in burning Some of the brick made from clay upland are to very dark red.

Harold Nayler and Jerry Smith

E Naylor: Stirling has about three feet of Red top clay underlaid by the Erie blue clay The upper clay is used in the manufacture of red stock brick which are made in a Martin machine operated by horse power The brick are dried in open hacks and are burned with wood in open shed scoved kilns The output of this yard is about five hundred thousand per season

Highway No. 7 did not pass the brickyard in those early years, so all he could view was a common pasture area from his bedroom window. Even after the highway was extended east of the Village, a huge steel culvert had to be incorporated under the highway in order that cattle had access to the pasture areas on both sides of the road.

Many of the red brick homes and business establishments in Marmora were built with bricks from the Nayler brickyard. Included on the list is

By 1911, the clay in the pond area had almost run out, so the Nayler family bought another brickyard in Trenton. The old brickyard area remained abandoned for years. The Village of Marmora purchased twenty-two acres of the property surrounding the brickyard with the intention that it would be developed for public use. Trails were cut through the bush surrounding the brickyard, picnic tables were installed and most of the plant and animal life identified and classified. As a result of Anne Philpot's creative work, "Nayler's Common Wetland and Trails" became a reality on August 6 , 1994 when the trails were officially opened to the public.

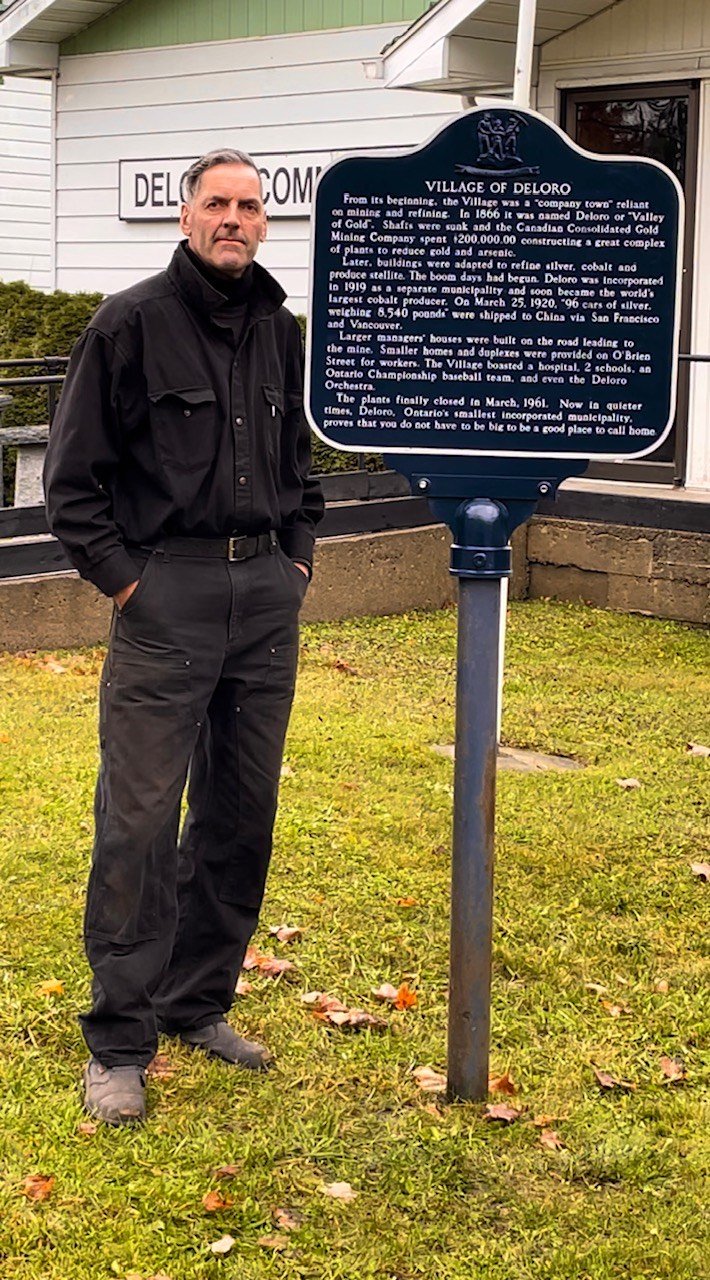

Nayler, John William, Brick maker, 1852-1925

Excerpt from 1906 Sessional Papers (Ontario)

Butwell Brothers Humber Bay Toronto - These yards are situated at the Humber and work a very mild sandy clay much like that found at Mr Russell's yard or at the yards on Greenwood Avenue. We have here a mild sandy clay the upper part of which burns to red brick while the lower gray colored clay burns to white or gray brick. Both these clays are dug in separate heaps and allowed to slake. They are then wheeled to Martin machines dried in an open hack yard and are burned with wood in the ordinary way in open shed scoved kilns. Butwell Bros have two yards having an output of something over two million per year

More notes on the scove kiln

The construction of a scove requires a level, dry area of land. Previously fired bricks, if available, lay bed face down to form a good, flat surface. Three or four layers of bricks are used to form the bottom of the tunnels. The width of each tunnel is approximately equal to that of two brick lengths. Three lengths of bricks separate the tunnels. Alternate courses are laid at right angles to each other (i.e. a course of headers, followed by a course of stretchers). Two short tunnels (e.g. approximately 2 m long) may be sufficient for a small number of bricks. For large numbers of bricks, tunnels cannot be longer than approximately 6 m. Otherwise, fuel inserted from both ends will not reach the centre of the tunnel. Large numbers of bricks are dealt with by extending the number of tunnels to cope with the requirement.

Butwell Brickworks, Toronto